Scales have been around since the 1700s which makes the weighing industry one of the oldest and most established in the world today. The expression goes, “everything that gets made, gets weighed,” and this is true! Scales started out as a true mechanical balance beam of sorts, utilizing counter weights to determine the weight on the other side of the scale. Obviously, things have progressed from there and almost everything is now electronic. Truck scales are no exception. Through the years our industry has seen a major shift in technology which has transformed the way our industry operates. Shifting the focus from the mechanical platform to now the diagnostics and data that a scale can produce.

Top 5 ways which Truck Scales have changed:

1. Mechanical Scales to Full Electronic Scales:

Mechanical beams and levers with many moving parts are a thing of the past. Truck scales now utilize electronics which provide greater accuracy combined with advanced troubleshooting capabilities. The scales with the least amount of moving parts are usually the most accurate, durable and provide the longest life.

2. Concrete Decks to Steel Decks

It’s fair to say that 30 years ago the majority of truck scales were concrete deck models. While concrete decks are still requested, steel decks have become more requested, almost 4:1. This is related to factors which include; ease of installation, increased serviceability and overall portability if you ever need to move your scale.

3. Concentrated Load Capacity (CLC)

This is the industry measure for how durable a scale is. Essentially, it is the measure of how many trucks can go across the scale over a given period of time before the scale starts to break down. Our industry has been largely trending toward a lower CLC which means a scale that handles less trucks and is built lighter, resulting in earlier replacement. We recommend a scale with a minimum of an 80k CLC for applications with less traffic and at least a 100k CLC for applications that start to exceed 50-60 trucks per day.

4. Attended vs. Unattended Weighing

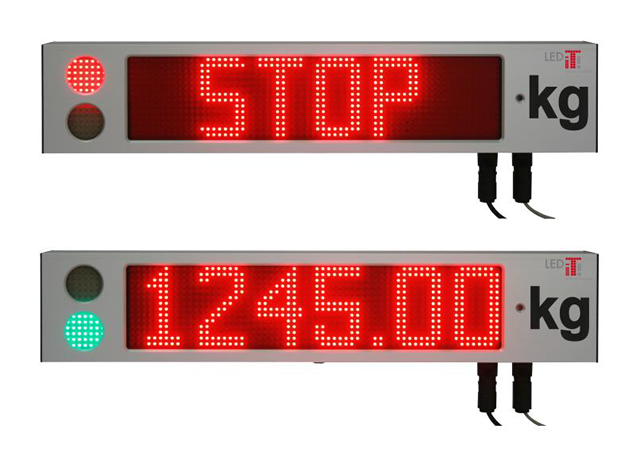

Efficiency is at a premium in every industry. Doing things faster and better is crucial to business, weighing operations are no different. Avoiding truck drivers getting in and out of their truck and spending time gathering tickets and other paperwork has become a large focus of our industry and has paved the way for unattended weighing. Kiosks, ticketing software, camera systems and stop lights are all part of the components we provide to help make your operation more efficient and effective each day. Unattended weighing means a safer operation and less reliance on somebody watching over the scale all day.

5. Digital vs. Analog Load Cells

Similar to how the progression from mechanical to full electronic scales was a major step for the industry, the same can be said going from analog to digital scales. Analog load cells were the introduction into the electronic world and while effective, they are comparably the analog TV signal to modern day HDTV, or the digital load cell.

Digital Load Cells have proven:

To be more repeatable

To be more accurate

To provide useful diagnostics

To be more serviceable

To be lightning-proof

To carry a longer warranty